As part of the new High Speed 2 (HS2) high-speed line, we are progressing on our site of 9 prefabricated segment viaducts. With UK Cares certified production, our Armaturis factory in Salon-de-Provence (Bouches-du-Rhône, France) is running at full capacity to supply couplers and anchoring plates. More than 500,000 connections (couplers and plates) are to be supplied until the end of 2025. (Client: Joint venture BBV: Balfour Beatty / Vinci)

Construction site: Delta Junction HS2 in Birmingham, UK

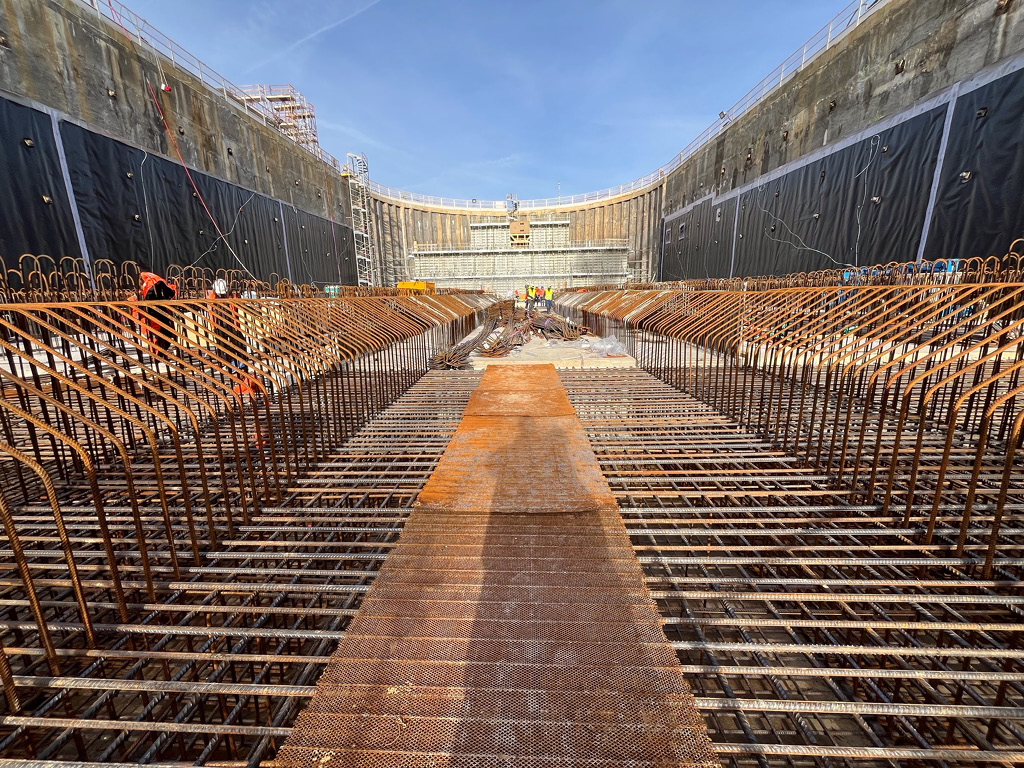

Construction site: Saint-Quentin-en-Yvelines station, line 18 lot 3, Grand Paris Express

As part of the Grand Paris Express, our teams started work on the Saint-Quentin-en-Yvelines station a few weeks ago, located on line 18. The Grand Paris Express (GPE) is a public transport network project consisting of four automatic metro lines around Paris, and the extension of two existing lines. With a total length of 200 kilometers, it will enter service between 2024 and 2030. The installation of the raft reinforcements is nearing completion, the elevations of the tympanum with the implementation of fiberglass reinforcements are being carried out in parallel and We are beginning the assembly cradles of the tunnel boring machine, which will begin in a few weeks to dig 6.7 km of tunnel to Versailles. (Client: Group Ferrovial / Spie Batignolles)

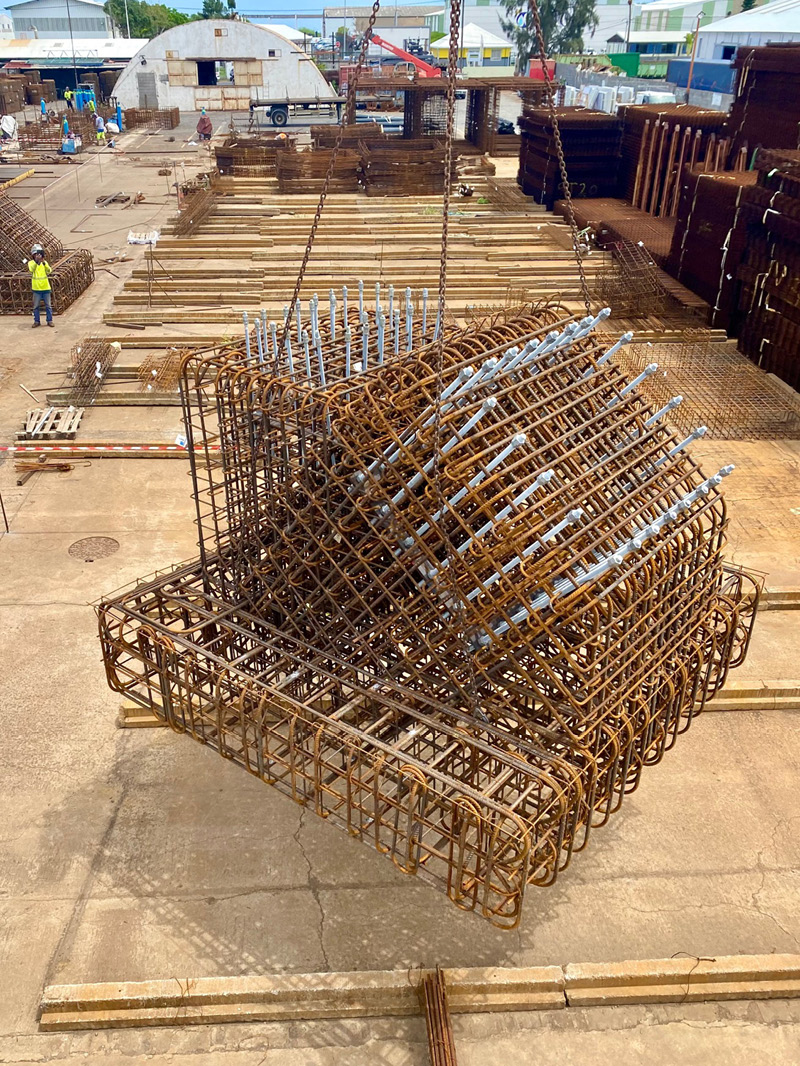

Construction site: Koungou wastewater treatment plant, Mayotte, France

Our teams are participating in the construction of the Koungou wastewater treatment plant. A wastewater treatment plant which constitutes a sort of model for the rest of the territory in order to face the challenges of Mayotte in terms of sanitation: improving the living environment of the population and preserving biodiversity. Funded by the State and the French Biodiversity Office, it is a station for 6 to 7,000 homes, which will be able to sanitize approximately 30,000 people. Reception is planned for the end of September 2024. The frames are prepared in the SAMT Ocean Indien Reunion factory, transported by boat to Mayotte then installed in formwork by our SAMT Pose teams… A complete service between two islands 1,500 km apart in the Indian Ocean. (Client: Colas Mayotte)

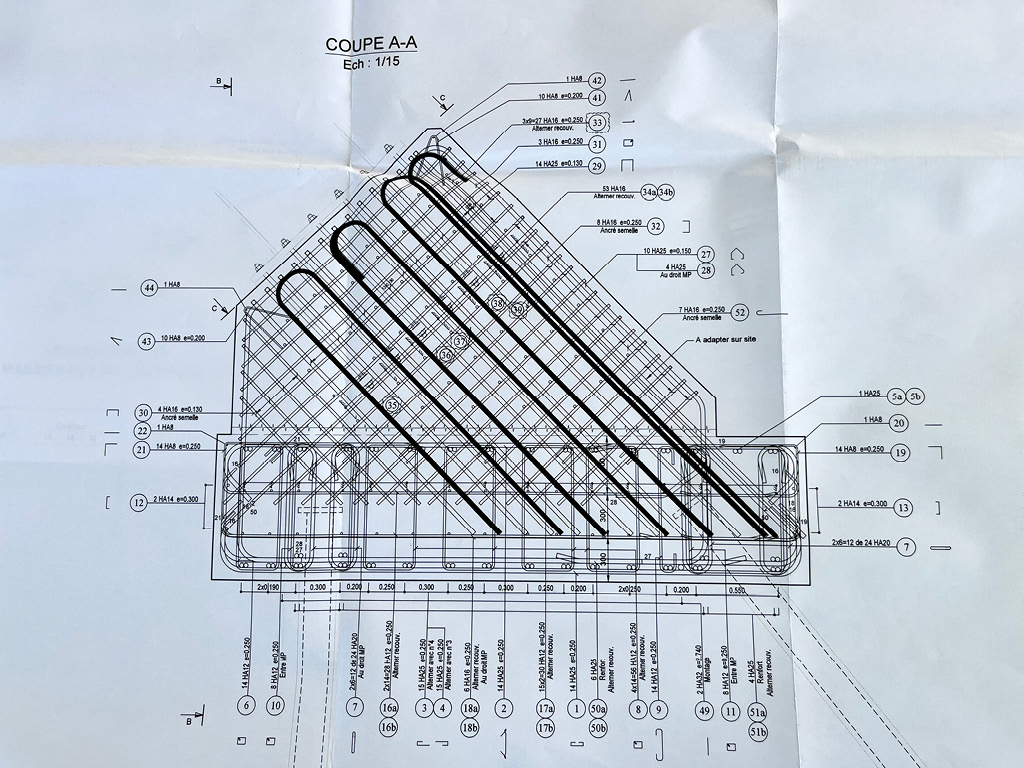

Construction site: new Larivot bridge in Cayenne, French Guiana, France

Let's go for the first elements of the Segments On Pile (SOP) of the new Larivot bridge... The SOPs are always the most complex parts of the work with high densities of reinforcement and external prestressing anchors. Our teams assemble the reinforcement cages using very precise templates to guarantee the perfect position of all the parts. The new bridge will include 19 SOPs, themselves broken down into 3 prefabricated concrete sub-elements. (Client: Joint-Venture Soletanche-Dodin Campenon Bernard)

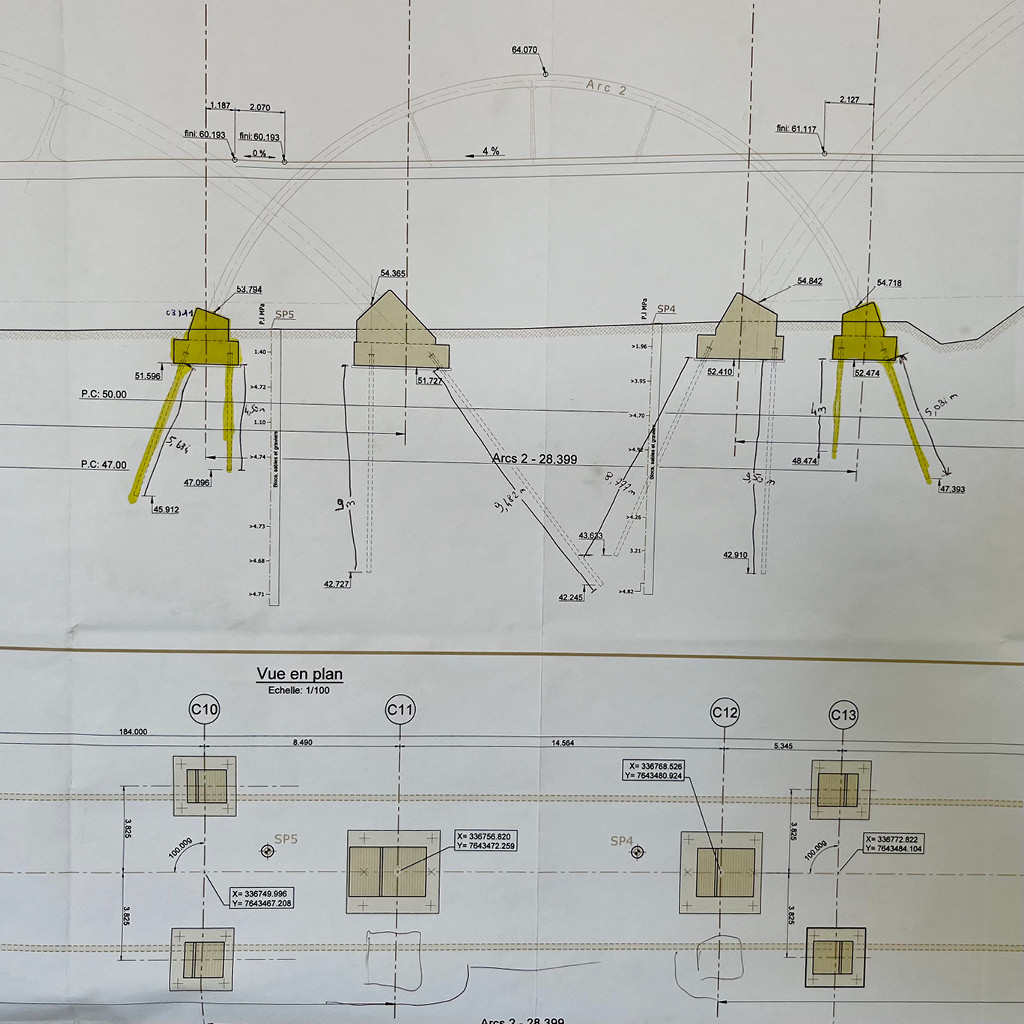

Construction site: ZAC Roland Hoareau pedestrian bridge in Pierrefonds, Reunion Island

Our Reunion Island teams are currently working on the future pedestrian and cycle bridge which will connect Pierrefonds village to the future ZAC Roland Hoarau, an economic activity zone of nearly 87 hectares. 300 meters long, this footbridge made up of a succession of arches will cross the 4 lanes. In order to reduce production times, the reinforcing cages for the foundation blocks which will support the feet of the arches are entirely prefabricated in our Le Port factory, including the embedded rods. These reinforcement cages are then delivered to the site and installed very precisely through micropiles. A great technical success. (Client: PICO Indian Ocean) (Photo credit of the computer-generated view: Altitude 80 Architecture)

New construction site: the retention basin of Captain Gèze, Marseille, France

In parallel with the construction of the overflow, we are installing the first “Buton beams” of the retention basin of Captain Gèze in Marseille. These beams will make it possible to carry out the earthworks inside the basin, then the civil engineering of the lower levels. This buried trilobe-shaped pool, 20m in diameter, has a capacity of 10,500 m3. Its mission is to store surplus water during rainy periods in order to compensate for the saturation of the networks and avoid discharges into the sea directly. (Client: NGE Génie Civil)

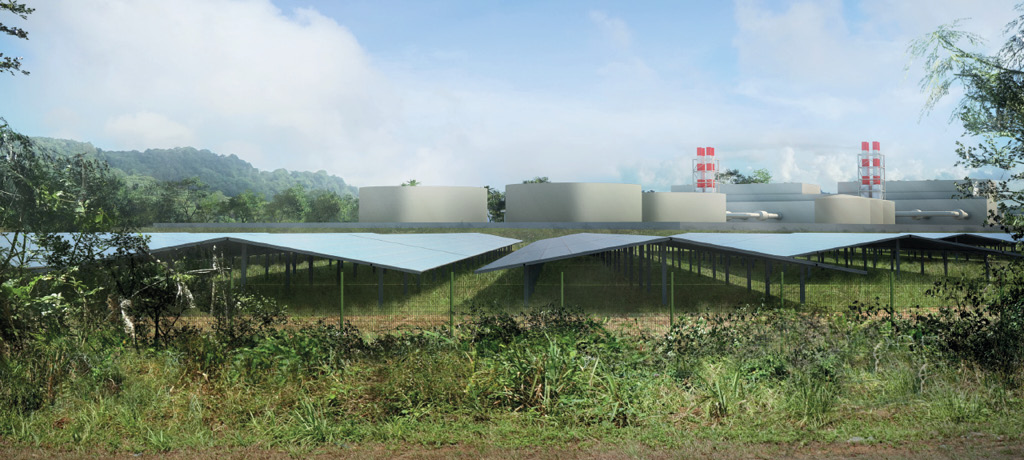

New construction project: the Larivot power plant, Guyana, France

Today, with 66% of its energy produced by renewable energies, notably thanks to the Petit-Saut dam, Guyana is already the French department with the highest rate of renewable energy. The Larivot power plant meets Guyana's ambition to reach 100% in 2030, or even before. It will provide a total guaranteed power of 120 MW to support the economic and demographic development of the coastline and secure the needs of the island of Cayenne. The armatures of SAMT attack the site in December! (Client: Groupement: Nofrayane / Sogéa / VCGP / Vinci DomTom) (Computer image: © EDF-PEI)

Construction site: dalot of the Saint-Joseph diversion, Reunion Island

Some news from the Indian Ocean, where we continue to develop projects, despite the sharp decline in the construction market that the entire profession has suffered since a little over a year. As part of the Saint-Joseph diversion, our teams are fully assembling the sections of the scupper intended for the flow of rainwater in Bois Noirs. These elements are then delivered ready to be concreted by our client. (Client: SBTPC-SOGEA)

Construction site: new Larivot bridge in Cayenne, French Guiana, France

End of assembly of the first pile header. The reinforcements are assembled in a template on the ground, then the entire element will be transported by a barge to the middle of the river to be placed in the formwork, in one piece. Remember that the construction of the new Larivot bridge, which will be 1,300 meters long, is described as a “technical feat” due to the complex geotechnical context. (Client: Joint-Venture Soletanche-Dodin Campenon Bernard)

Construction site: Delta Junction HS2 in Birmingham, UK

As part of the new High Speed 2 (HS2) high-speed line, we are progressing on our site of 9 prefabricated segment viaducts. For several weeks now, the Kingsbury prefabrication plant has been producing segments on piles (SOP) and segments on abutments (SOA) in series. Given the weight of the elements to be handled and transported, each SOP is manufactured in two half elements which will then be assembled at the time of installation. The reinforcement is very complex with numerous inserts to be incorporated into the reinforcements. (Client: Joint venture BBV: Balfour Beatty / Vinci)