High-quality steel columns with base plates and integrated inserts, prefabricated by our SAMT Indian Ocean teams, are now heading to the Albioma site at Bois Rouge. These structures will be part of the new waste-to-energy (WtE) unit, which will convert 70,000 tons of waste into electricity using refuse-derived fuel (RDF) — a major step forward for the island's energy transition. Proud to deliver local expertise in support of a circular economy! (Client: SBTPC / SOGEA Réunion)

Project: WtE / RDF Bois Rouge - Réunion Island

New construction project: Steam Generator Storage Building (BEGV) – Saint-Alban Nuclear Power Plant, Isère, France

This building will temporarily house the four original steam generators from Unit 2, replaced as part of a major maintenance operation led by EDF. A truly XXL-scale project — not only due to the size of the equipment (each weighing over 300 tons!) but also because of the high technical and safety requirements. SAMT is proud to contribute its expertise to such a sensitive project at the heart of the French nuclear industry. (Client: Bouygues Construction Expertises Nucléaires)

New construction site: High-Speed Train Maintenance and Stabling Facility (SMR) in Marcheprime, Gironde, France

This 14-hectare center will accommodate up to 20 high-speed trainsets (TAGV) for Level 1 to 3 maintenance operations, operating 24/7. It will feature a 300-meter main hall equipped with inspection pits, overhead cranes, lifting columns, and retractable catenaries. Designed with an innovative wooden structure, the project is certified “Bâtiment Durable Nouvelle-Aquitaine – Silver level”, reflecting a strong commitment to decarbonizing rail transport. The construction will involve up to 400 workers over 30 months, with commissioning scheduled for 2027. Ultimately, the site will create 200 sustainable industrial jobs. This project represents a significant step towards opening up the French rail market to competition and advancing low-carbon mobility. A strategic project led by LISEA and entrusted to Spie Batignolles.

New construction site : The Monte Sorting and Recovery Center (CTV), Corsica, France

SAMT is proud to contribute to the construction of the Monte Sorting and Recovery Center (CTV), a major project for sustainable waste management in Corsica.

Scheduled to be operational in 2027, the CTV will process up to 98,000 tons of waste annually, reducing household waste landfilling on the island by 25%.

This innovative public facility will include:

• A closed-building composting platform for bio-waste and green waste.

• Sorting lines to extract recyclable materials and produce Solid Recovered Fuel (SRF).

• Facilities adhering to strict environmental standards to minimize nuisances.

Funded 80% by the State through the Transformation and Investment Plan for Corsica and ADEME, this project represents a €71 million investment.

As a committed stakeholder, SAMT is contributing to the realization of this essential infrastructure for a local circular economy.

(Client: Natali)

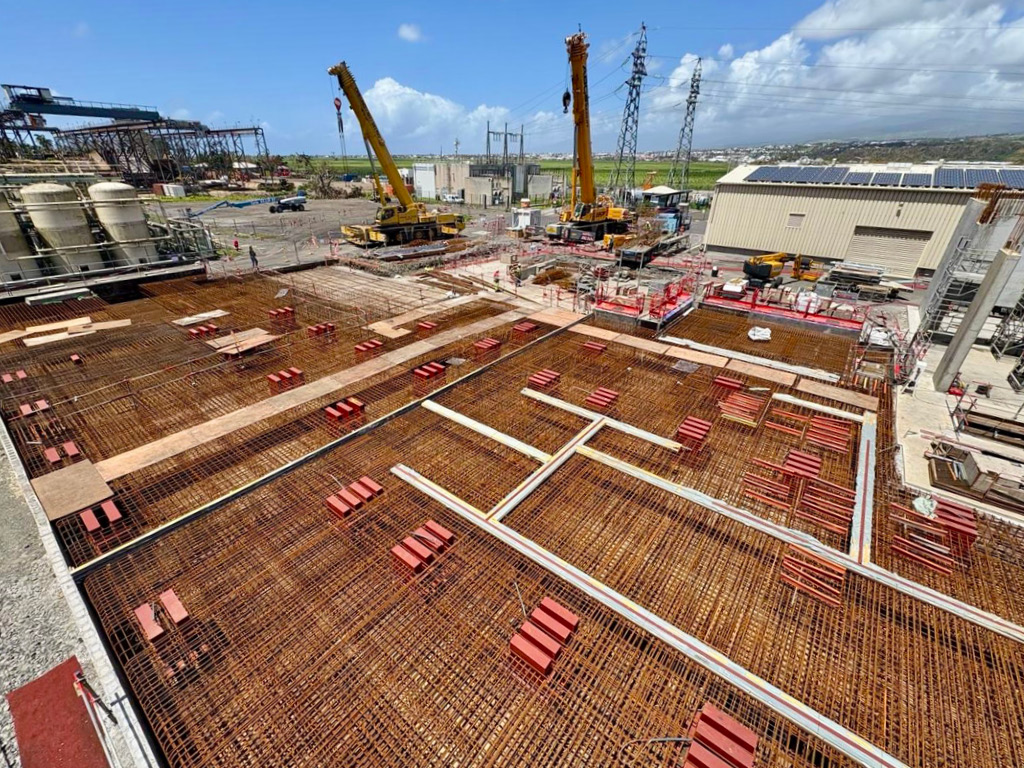

Construction site: CSR Energy Recovery Center at Albioma Bois Rouge (ABR), La Réunion

Our teams are progressing with the raft foundations for the future boiler designed for the energy recovery of Solid Recovered Fuels (SRF/CSR).

Every year, 70,000 tons of CSR are produced in La Réunion from sorted waste (wood, textiles, plastics). These high-energy-density fuels, currently underutilized, will now feed a new boiler built within the Bois Rouge industrial site.

This boiler will connect to an upgraded turbine that allows dual steam inputs (CSR/bagasse-biomass). The project will reduce biomass imports and help meet the goal of 72% of household waste treated and recovered.

♻️ A flagship project supporting the island’s energy transition!

Client: SBTPC SOGEA Réunion

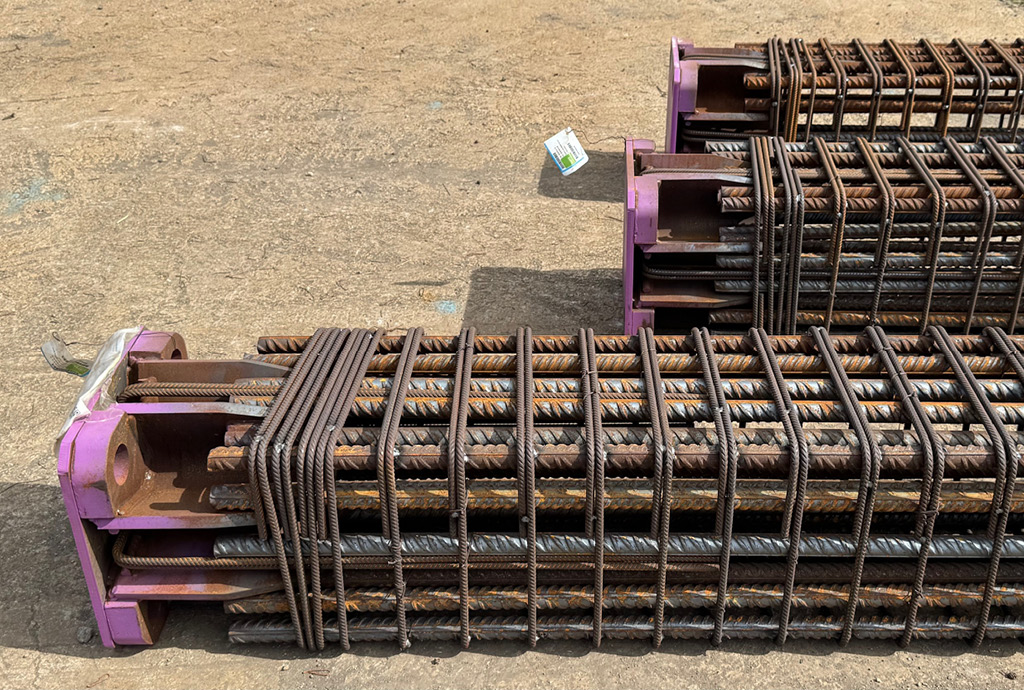

Construction site: new Larivot bridge in Cayenne, French Guiana, France

Have you ever seen a segment made entirely of stainless steel reinforcement? It's beautiful, isn't it? We have just assembled two of them on the New Larivot Bridge in French Guiana. These are the two segments on abutments C0 and C20. The use of stainless steel reinforcement will allow these two elements to resist corrosion and extend the life of the structure in a very aggressive environment (mangrove with tidal range). These reinforcements are grade 1-4462, they were cut and shaped in mainland France in our Salon-de-Provence factory, transported by sea freight to French Guiana, and finally assembled by our teams on site. (Client: Joint-Venture Soletanche-Dodin Campenon Bernard)

Construction site: Delta Junction HS2 in Birmingham, UK

After many months of hard work, our SAMT Rebar teams are now completing the final pier caps for the 97 piers we have built to support the viaducts of the Delta Junction. All methods, templates, lifting, and transport studies were carried out by SAMT Engineering. The solution chosen with the client: prefabricating all pier caps in a dedicated area using templates, then transporting them to each support and installing them in one piece into the formwork. Each pier cap weighs around 10 tons—quite a challenge! (Client: Joint venture BBV: Balfour Beatty Vinci)

Certified!

Still hard at work on the Delta Junction construction site in Birmingham, our UK subsidiary SAMT Rebar Ltd starts 2025 with ISO 9001 certification. Well done to the teams!

Best wishes for 2025

Weaving links

As early as the Middle Ages, the verb weave acquired a figurative usage: “to assemble, create or form something with care”. That's what we do every day!

Together, let's continue to weave links and build a successful future.

Happy New Year 2025!

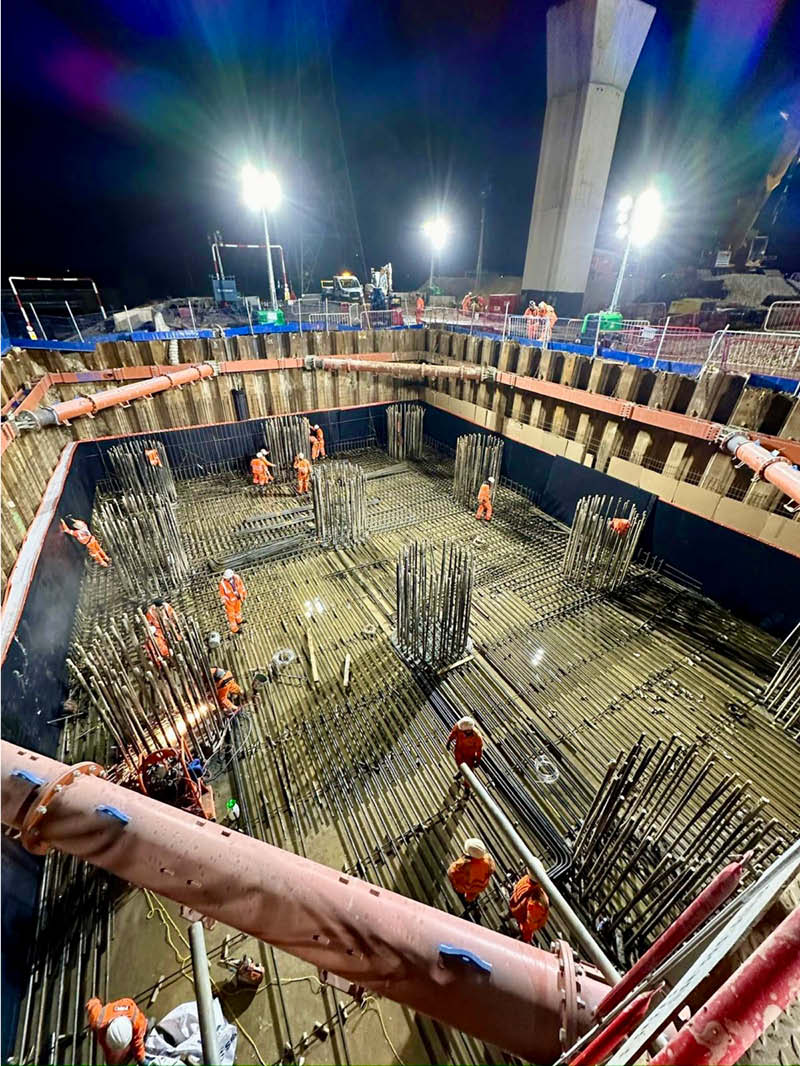

Construction site: Delta Junction HS2 in Birmingham, UK

Our SAMT Rebar teams have just accomplished a remarkable feat on the Delta Junction HS2 site. As the A11 abutment footing of the River Tame West viaduct was very critical to the overall site schedule, our customer asked us to deploy major resources to lay the footing reinforcement as quickly as possible. The 330 tonnes of reinforcement were laid and delivered in 12 days of intensive work, with 2 shifts working 7 days a week.

The challenge was met! A big well done to our teams.

(Client: Joint venture BBV: Balfour Beatty Vinci)